THE BRITISH OVERSEAS RAILWAYS HISTORICAL TRUST

|  |

Kevin Jones' Steam Index

Journal of the Institution of Locomotive

Engineers

Volume 22 (1932)

| The IMechE virtual library may be accessible (full papers, all diagrams, photographs, extensive tables, etc).via Sage |

Graham, E. (Paper No. 284)

Progressive methods applied to a modern overhaul shop for electric rolling

stock. 4-62. Disc.: 62-7.

Fourth Ordinary General Meeting of the 1931-32 Session held in the

Hall of the Institution of Mechanical Engineers, Storeys Gate, Westminster,

on Thursday, 7 January at 6 p.m. In the absence of the President, owing to

illness, the chair was taken by Mr. H. Kelway-Bamber who introduced the

speaker..

Account of the highly organized and productive workshops at Acton enjoyed

by London Transport. In the discussion Gresley (62-3) was very impressed by the high mileages achieved by the rolling stock,

but was informed that tyre life (70,000 miles) was short. He also noted the

very hard tyres and that it was possible to employ Ferodo brake blocks because

of the high mileage in tunnel. J. Clayton (64) noted how labour was reduced

at Acton Works and H. Chambers (65) noted the belt system adopted by the

LMS for locomotive repairs..

Sanders, T.H.

Chairman's Address: rival traction systems. 91-103. Disc: 104-10.

Second Ordinary General Meeting of the North Eastern Centre (Session

1931-32) held at Hotel Metropole, Leeds, on Friday, 23 October, 1931, at

7.15 p.m., the chair taken by Chairman of the Centre, Mr. T.H. Sanders who

invited Mr. J. Blundell, Vice-Chairman, to take his place. who in turn invited

Mr. Sanders to read his Address as Chairman of the Centre.

Consideration of the export markets for steam and electric traction. Considered

that the United Kingdom lacked many of the factors which drove electrification

elesewhere, such as lack of domestic coal reserves, lack of long gradients,

long tunnels and long hauls.. No gains could be made through regenerative

braking. Freight trains could not be increasemd in length over what are now

hauled, owing to existing loops and refuge sidings; 700,000 private owners'

wagons of the cheapest possible construction with the cheapest possible

equipment, and the !owest possible standard of maintenance; lacking continuous

brakes with the shortness of block sections in congested areas. Wagons cannot,

except for certain special services, be made seriously different to the standard

12-tonner, due to port hoists, works sidings, etc. The passenger traffic

on the main lines is already scheduled .as fast as track alignment, service

requirements and regard for punctuality will permit – not forgetting

also existing agreements between certain railway administrations for time

limits between certain towns. In response tosuburban electrification noted

the successful use of steam push and pull operation in France using powerful

2-8-2Ts. Noted the Weir report, but was very cool in his response to any

form of electrification even of suburban services. The increasing imports

of fuel oil for road vehicles, the possible use of diesel electric locomotives,

and within the same context mentioned the Heilman steam electric locomotives.

J. Blundell (104-6) mentioned the problem of flooding and the vulnerability

of overhead systems to damage in war. H.I. Andrews noted that in Italy overhead

electrics coped well with floods, and considered that there was a trend towards

electric traction. E. Windle (110) contributed.

The Address was repeated at the Second Ordinary General Meeting of the Manchester

Centre held at the Literary and Philosophical Society, 36, George Street,

Manchester, on Friday 4 December at 7.0 p.m., the chair being taken by Mr.

S. H. Whitelegg (Chairman) p. 111.

Collins, F.R. (Paper No. 285)

The relationship of loading gauge to running gauge and the effect of both

on speeds round curves. 121-41. Disc.: 141-54. 28 figs.

Fifth Ordinary General Meeting of the 1931-32 Session held at the

Institution of Mechanical Engineers, Storey's Gate, London, on Thursday,

28 January, 1932, at 6 p.m., Mr. J. Clayton,, Vice-President, occupying the

chair

Anyone with experience of narrow gauge railways, that is to say, railways

with a running gauge of 3ft. 6in. or less, must have been struck by the fact

that the loading gauge is very much greater in proportion to the running

gauge than is the case on railways of 4ft. 8½in. and over. Apparently

the loading gauge adopted in England 100 years ago was the result of road

experience in the same way that 4ft. 8½in. seems to have been a gauge

used for road vehicles, including chariots, and adopted later for tracks

of either wood or metal to give easier haulage €or the horses then employed.

At any rate, a loading gauge 9ft. 0in. wide by 13ft. 0in. high appears to

have been thought sufficient and tunnels, bridges, platforms, etc., soon

definitely settled the matter as far as England was concerned. Some other

countries adopted a more liberal loading gauge, but as far as the Author's

experience goes, 11 feet wide by 16 feet high is about the maximum for the

4ft. 8½in. gauge, and that only in rare cases. The loading gauge for

railways of 5 feet running gauge and over, does not appear to be very much

greater than that adopted for the 4ft. 8½in. and the greatest width

noted is 12 feet. The relation of loading gauge to running gauge on normal

and wider gauges may therefore be taken as from 1.9 to 2.3 to 1 as regards

breadth, and 2.7 to 3.4 to 1 as regards height. The 3ft. 6in. gauge usually

employed a loading gauge 9 feet wide by 13 feet high: that is comparable

with the British standard gauge.

Discussion: W. Cyril Williams (144-6) speeds on the 3ft. 6in. gauge:

Beyer-Garratt in South Africa did 61 mile/hour on test, and rode perfectly

on curves at the highest speeds, but the larger the vehicle on any gauge,

the lower the safe speed, and the greater the necessity for good maintenance.

J.D. Rogers (146-8) considered that a high centre improves the riding qualities

of the engine; low centre of gravity causes damage to track. He recalled

a railway which ran a mixed electric and steam service. The steam engines

hsd 6ft. 6in. wheels and doing schedules of 50 to 60 mile/hour. The electric

engines, with 50in. wheels, were put on the same line and the question was

what should be the speed and elevation of the rail for the same speed? The

line had not been in operation very long when a disastrous wreck occurred,

and it was reported that the electric engine had sheared the spikes holding

the outside rails, due to thrust caused by the low centre of gravity. He

had ridden locomotives in America with 80in. coupled wheels at 80 mile/hour

when the oscillation of the engine had been terrific but entirely safe. I

do not know why people are so concerned about the centre of gravity. 120-ton

capacity coal cars, tare 40 tons, never derailed whereas 50 and 70-ton cars

jumped the track. S.R.M. Porter (148-...) included a table based on ratios

of velocity to gauge and the square root thereof (where 2 is the

latter).

| Normal speed | Max speed | |||

| Gauge | 1 |

2 |

1 |

2 |

| 5ft 6in | 61 |

66 |

86½ |

93½ |

| Standard | 56½ |

56½ |

80 |

80 |

| 3ft 6in | 48½ |

42 |

69 |

59½ |

| 2ft | 37 |

24 |

52 |

34 |

| 1ft 3in | 29 |

15 |

41 |

21½ |

The normal running speed for the 15in. gauge was calculatemd at 29 mile/h and he had often timed trains on the Romney, Hythe and Dymchurch Railway at 27 mile/h., which seemed sufficiently near. The maximum speed is calculated at 41 mile/h: Locomotive Magazine (15 Sept., 1928) reported speed of 38 mile/h. on the Eskdale Railway. With the track in good condition, therefore, and with scale model vehicles, it seems that the theory of the speed being proportional to the square root of the gauge holds good. D.R. Carling (150-2) supported these observations with comment on speeds attained on Romney Hythe & Dymchurch Railway.

New goods tank locomotives, class "W" on the Southern

Railway. 155-6. illus., diagr. (s. & f. els.)

These new locomotives are practically identical with the three-cylinder

Goods Tender engines Class N1 with the addition of side tanks, bunker and

a trailing bogie. They are intended mainly for the heavy goods traffic in

the Metropolitan area and other short distance goods workings elsewhere.

The engines are fitted with a powerful and graduated steam brake, working

in conjunction u ith the vacuum brake on the train when required, the brake

blocks being applied to all wheels except the leading pony truck.

Journal No. 106

Meeting in Newcastle-on-Tyne, 20th October, 1932. 160-1.

The First Orrdinary General Meeting of the Newcastle-on-Tyne Centre

(Session 1931-32) was held in Room 11, Central Station Hotel, Newcastle-on-Tyne,

on Tuesday, 20 October, 1931, at 7.15 p.m., the chair being occupied by the

new Chairman (Mr. P. Liddell) who introduced Mr. W. Scott, who read his Paper,

entitled, “Iron Foundry Methods (with special reference to Locomotive

Work)", which was followed by a discussion.

Blundell, J. (Paper No. 287)

Locomotive delays and their causes. 186-209, Disc.: 209-23. 1933, 33,

287-90.

Third Ordinary General Meeting of North Eastern Centre (Session 1931-32)

held at the Hotel Metropole, Leeds, on Friday 20 November, 1931, at 7,15

p.m., the chair being taken by T. H. Sanders.

Although not stated explicitly, it is obvious that this paper was based on

experience gained at a motive power depot on the former GNR lines in the

West Riding of Yorkshire. The locomotive stock included: B6 4-6-0s, J39,

J2, J1, J3/7, O1 and O4 tender classes and N1, N2, C12, J50 and J55 tank

engines. The water was regarded as being of good quality but the gradients

were severe (1 in 45). Only short mileages were run. Slipping was the most

serious problem encountered in service and the author blamed the sanding

gear where 50% was dry (98 incidents) and the other 50% steam (81 incidents).

Neither system was effective on snow. The Lambert system was good but was

liable to excessive waste and to freezing. One major advantage was that it

did not need dry sand. The author sought a method not based upon sand.

The failure to steam properly led to considerable delays to passenger trains

(representing 500 minutes out of a total of 1800 minutes lost) and this was

attributed to strange engines and smokebox problems. Blast pipes out of alignment

was a problem mentioned. There were two brick arch failures and these stemmed

from poor construction. Water leakage from tanks led to hot boxes. In the

discussion at Leeds C.O. Becker (210-11) suggested locating the sandboxes

on top of the boiler and considered that compressed air was better than steam

for delivering sand, leaking tubes could be cured by welding and the Japanese

had eliminated broken couplings by using automatic couplers. D.C. Stuart

suggested that compressed air (80 psi) tests on boilers showed up blowing

in smokeboxes. He had experienced no problems with injector steam cones.

Thackeray mentioned axlebox heating. Manchester Meeting 8 January 1932:

Whitelegg (216-17) mentioned tubes, injectors, jointing materials and compressed

air sanding as adopted by the GER. Attock (217-18) noted that the use of

dry sand led to track circuit problems. He considered that the addition of

limestone to the firebox helped to eliminate clinker. Doherty (218) commented

on tender feedwater cocks. Bond (218-20) requested a definition of how casualties

were assessed on the LNER. He considered that there were an excessive number

of crank-pin washer faults. He considered that the arrangement of trimmings

for axlebox lubrication was unsatisfactory. Caldwell (220) discussed his

own experience with broken coupling rod crank pins. Mercer (220-1) discussed

jointing materials. Meeting at Newcastle-on-Tyne on 31 January 1933.C.C.

Jarvis noted the problem of slipping, even with sanding gear in good order,

on poor track, such as sidings. Pargitter (288-9) considered that better

design of sanding gear was required. J.W. Hobson (287-8) noted that Lens

joints introduced to Hawthorn Leslie & Co. from the USA had reduced pipe

fractures..

Poole, A.J. (Paper No. 288)

Locomotive smokeboxes. 281-98. Disc.: 298-318.

First Quarterly Meeting of 1932 Session held at the Locomotive Running

Shed of the Buenos Aires Western Railway at Mechita on Saturday 5 March,

1932. J.G. Mayne, Chairman of the Centre, presided. The following critera

were sought:

- A draught well distributed over the whole range of tubes.

- A minimum of " eddy space."

- A maximum of draught for a minimum of back pressure.

- Absence of spark throwing without the use of any of the thousand and one curiosities, specifications of which fill the Patent Libraries of world.

- The final exhaust from the chimney top tends to clear the cab instead of beating down at all speeds and all cut-offs.

- Simplicity and accessibility.

Poole considered the conditions contained in the original smokebox

of The Rocket and observed that criteria Nos. 1 and 2 were well

met, but No. 6 (simplicity): "a more inaccessible arrangement is hard to

imagine" The blast-pipe nozzle was well up the chimney: an arrangement which

may called a "suction" principle as distinct from the type in which

the nozzle is well below the chimney throat (classified as the "impulse"

type). The eddy space, by which is meant space outside the direct line of

flow from tubes to chimney, is practically nil, while the draught on the

outlying tubes, owing to the curved form of box, is practically as good as

on those in the centre. These features may have contributed in no little

extent to the signal success of the Rocket at the Rainhill trials,

and it seems a pity that in later engines the normal box form with front

doors was developed.

The presence of the nozzle in the throat of the chimney led to the

"impulse type" where the tendency of the gases is to take a direct path from

each tube to this point. It is obvious in this case that the tubes nearest

the nozzle, that is the middle tubes of the top rows will obtain all the

benefit while the outer tubes of the lower rows may suffer to the extent

of having a return draught to the firebox induced in them, especially if

working with a heavy fire. The eddy space has made its appearance too in

the lower front corner especially, while the tendency to excessive spark

throwing is obvious. The entraining cone, too, is very short. It is probable

that with a firebox having a very limited heating surface intense draught

through the top tubes is, beneficial in that it lifts the flame into contact

with the most valuable part of the heating surface, i.e., the flat

roof.

If the nozzle is lowered, the eddy space is hardly affected, but a

greater number of tubes in the middle zone are brought into direct

draught line and the spark throwing becomes far worse than with the original

impulse type and this led to the extended smokebox, which in combination

with a high nozzle is an excellent spark preventer. A low nozzle under

the same conditions retains the disabilities associated with it, except that

a greater storage space for cinders is available. An immense eddy space is

created by this extension, but the theory that the draught is more equalised

over the tubes is untenable as after the first few exhausts a relative

equilibrium is established and the gases still take the shortest path. The

energy for maintaining a vacuum in this large space is

considerable.

Experiments with various forms of deflector plate eventually led to

the American front end where a certain amount of equalisation was gained

by lengthening the path of the gases, and by tending this path forward, a

great saving of eddy space was attained. At the same time as the cinders

impinged at the several deflection points they were broken so small that

by the time they had filtered through a wire netting diaphragm they were

quite harmless. But it was found that 35% more energy was required to draw

the gases past this complicated system of baffles.

Except on the Great Western Railway the extended smokebox did not

meet with any great favour. On the LNWR. Webb divided his smokeboxes into

two compartments by means of an horizontal plate and provided a chimney and

blast-pipe to each. Unfortunately he used a separate exhaust for each cylinder

without any junction, so that the very intermittent effect rather nullified

the experiment .

The next move came. with the introduction of the modern large diameter

boiler, which had the effect of shortening the external portion of the chimney,

and to compensate for this an internal extension was frequently used .

Discussion; Mr. A. E. Bright (307): The Author has shown us

how the smokebox has developed since the days of the “ Rocket,”

and now gives us food for thought with the “Clayton” smokebox.

This Paper, together with a previous papci , No. 241, by E. Windle, should

prove a useful reference on the subject of smokeboxes.

Whilst undoubted1y the proposed “Clayton” smokebox has good points,

one rather wonders how it would serve in practice. The average British-built

locomotive has a ratio smokebox volume+grate area of between 5 and 6. From

Fig. 13 of the Paper under discussion, this ratio, in the case of the Clayton

smokebox, would appear to be in the neighbourhood of 3, which is small, and

this being so, the fire would probably be disturbed, especially with two

cylinder engines, and, as a result, even more smokebox ash might be found

in the smokebox than is usual. It is stated that dead smokebox ash would

be blown forward by a secondary jet and thence through the chimney, but it

is probable that much of this ash would lodge around the base of the blast

pipe; and that which was blown through the chimney would give considerable

annoyance to passengers travelling in the train.

Returning to the smokebox of normal design, the Author has not mentioned

the vexed question of parallel versus coned chimneys, and knowing him to

be very interested in this question at one time, I would be interested to

know if he has had the chance of trying the one against the other, and if

so, what are his conclusions? Various formulae are available for smokebox

proportions, but an analysis of these will give conflicting results it is

extremely doubtful if it is possible to give one formula to suit all engines,

and if so it would be far too unwieldy for common use. The only way to get

maximum efficiency of blast pipe and chimney is by trial and error, and tests

should be carried out on all new types of engines put in service. I am of

the opinion that many existing engines in this country could be improved

by increasing thc diameter of both chimney and blast-pipc nozzle. I have

heard of one case where the diameter of blastpipe nozzle was varied according

to whether the engine was on passenger or goods service, and favourable results

were claimed.

The Author mentions the G.W.R. jumper-top blast pipe and states that without

frequent attention this soon carbonises up solid. From personal.experience

I can say this is only the case when the engine has been consistently

overlubricated, and in any case, the nozzle can be easily and quickly cleaned.

This device was designed to operate at starting and at cut-offs, between

40 and 75 per cent. at slow speeds. Its action depends on pressure of the

exhaust steam, independent of its velocity. The jumper top has been very

successful, as is evidenced by its having been fitted on the new "King" class

locomotives. No doubt many cases of bad steaming engines are due to incorrect

alignment of blast pipe and chimney. 'rhese should be set by means of a gauge

rather than the antiquated plumb-line method ; such a gauge can be cheaply

made. Smokebox accessibility does not appear to receive due attention from

the designer.

British-built locomotives continue to appear with large smokebox doors. I

notice that the new Western Rly. engines have arrived without the central

dart, and would be glad to know if the clamps alone have proved satisfactory.

North American practice is to fit only a small door, and when necessary to

change outer tubes the front plate of the smokebox must be removed. After

seeing a photograph of a most wonderful smokebox front on the cover of the

latest Baldwin Locomotive Mngnsine, one gathers that the changing of a tube

in a North American shed must be quite a serious business, or possibly they

may have some method of eliminating tube trouble which is not yet known in

the Argentine.

H. Holcroft:(431-) Like many others, I have looked

forward to hearing this Paper very much indeed. The blast-pipe an9 chimney

together form one of the most important parts of the locomotive, which comprises

two distinct units-the boiler, complete with the smokebox, ash pan, and so

on, and the engine part with the cylinders, motion, frames and wheels. There

is no connection whatever between these two umlts, except the jet at steam

which escapes from, the cylinders, through the blast pipe, and that is the

one connection between the two that makes the locomotive a single unit ;

and everything depends on the efficiency of the ,apparatus through which

that exhaust jet passes. For .instance, an engine may have a very high tractive

effort, ,but unless the boiler generates enough steam it cannot -sustain

a high tractive effort when running. On the .other .hand, if there is plenty

of steam, it may be that through excessive back pressure the locomotive cannot

develop its -full horse-power, due to choking by a, restricted blast-pipe

orifice to 'get the necessary draughts.

With regard to ash pan and damper openings, Mr. Sanford called attention

to the question of the use of front and back dampers, the idea being that

when the front damper is open -an inrush of air is obtained which assists

in the draught. I have tried on many occasions, with different locomotives,

the effect of changing from front to back opening while running, and vice

versa, but have never detected the slightest influence on the draught; as

far as I can see, it does not make any difference at all. On the other hand,

when running through a tunnel or a long, low bridge with only a small regulator

opening it often happens dhat a sudden tongue of flame shoots out of the

fire-hole, simply because the air is confined and there is no lateral , spread

of the air under the engine; it cannot get away, with the result that a sudden

increase of pressure occurs in front .of the ashpan and the air rushes in;

but apparently in the ordinary course of running the air is dragged along

with the 'locomotive, or projected out sideways, so that this increase of

pressure that the Author rather relies on does not materialise in practice.

As regards the air openings through the grate and fuel-bed, I was very much

struck during one of the coal strikes when the supply of English coal ran

out and we were using some American coal of rather lower calorific value

than the ordinary English, that the steaming was nevertheless very good,

and the reason I attributed that to was the fact that it was a screened

coal—that is to say it was more or less of a uniform size—and hence

the openings through the fuel were regular, and therefore there was a very

much nearer, approach to ideal conditions of combustion than occurs in the

ordinary way, where the coal is a mixture of lumps and fine dust, so that

there are irregular openings in the fuel over the grate. With a screened

coal about the size of road metal, it seems to make combustion very efficient.

As regards the fire-door, nothing has been mentioned abl)(Jt the shape of

the fire-hole. It has been my experience that engines with an oval or

approximately oblong opening are much better steamers than those with a round

opening. My view is that with the round fire-hole and the half-round deflector

there is a much gTeater bunching of cold air, which reaches the tubes in

the middle of the tube plate, whereas in the case of a wider and less deep

opening with a more or less level top the air gcts spread out better. A device

by which firemen can often make a shy steaming engine steam well, is that

of putting a piece of plate across the lower third of a round fire-hole and

firing over the top of it. Apparently the air, in striking the sharp edge

of the plate, is deflected downwards on to the fire instead of going direct

towards the tube plate.

The position of the chimney on the smokebox has already been referred to

by Mr. Chambers, but it has been my experience that it is better to situate

the chimney well forward, because it br ing s about a better distribution

of the draught over the front tube plate and the gases do not have to take

such an abrupt turn to reach the vertical.

On the question of nibs, bars, corrugations, etc., .in the blast-pipe orifice,

to produce eddying and so entrain more gas, it is doubtful whether this is

really an 'advantage, because the result is to increase the contact area

of the steam with the soli cl surfaces, and so reduce its velocity. Also

there is the question of the carbonisation of the blast-pipe, which becomes

furred up with carbon deposit in a very short time, and this collects under

any projections in the orifice. I believe, in fact, that was one of the reasons

for the Adams vortex pipe being abandoned-the difficulty of removing the

carbon deposit from the narrow annular orifice.

As regards the action of the exhaust steam in producing draught, nobody seems

to have come to a definite conclusion as to what really takes place, but

apparently several actions occur ; there is a certain amount of ejector action

due to surface contact of high velocity steam with .thc gases, a small amount

of entraining of the gases, and to some extent, perhaps, a piston-like action

of plugs of steam 'in the chimney with each exhaust beat which sandwich the

gases between them and so it seems to be a mixture of those three in varying

proportions. Another thing about the blast-pipe is that it is always assumed

that the steam comes out of the blast orifice at equal pressure all over,

but I was verry much struck when travelling on the leading engine of a pair

gomg through a long tunnel on an up-grade, in watching the sparks coming

from the chimney of the second engme, which was an old saturated engine with

the steam-chest b.etween the cylinders. As the. sparks came out they made

a different angle of incidence with the sloping tunnel roof with each of

the four beats in a perfectly rhythmical manner, showing that the direction

of the steam and gases took a slight change with each beat, and I put that

down to the fact that possibly the direction from which the steam came.from

the cylinders made a difference. Perhaps t.hrough being a saturated engine

a certain am?unt of mOlstur.e came up with the steam and was projected to

one side, and It evaporated at or near the blast-pipe orifice where pressure

changed to velocity, so that there was a ddlerenc of denslty in the blast-pipe

orifice itself which deflected the jet slightly. That may be an explanation

as to why an engme with its valves badly out of beat is often a bad steamer,

because the effect of the blast is more pronounced in one direction than

another, and thus have the same effect as if the chimney and blast pipe were

out of line.

Colonel Kitson Clark: (433) I have not very much to add, except one

or two historical points, . One is the story about the blast-pipe in the

Rocket. I believe that the father of our friend Sir John Dewrance also

worked on that blast-pipe all night, as there was a record passed to

Sir John many years ago as to his father's connection with the story.

With regard to what M.r. Holcr~f~ said about the oval fire-hole door, I had

the privIlege of ndu:g on the top of the boiler of an Atlantic type locomotive

that ran- from Philadelphia to Atlantic City in 1897. The firebox, as far

as I remember, was styled Wootten. It had two fireholes and the coal was

exactly what has been descnbed-plcked pieces, rather smaller than one's fist,

over the whole of th.e grate area, and they practically did not add any fuel

during any time of the run of 47½ miles. The engine steamed extraordinarily

well, and perhaps rather from its, own merits than my approving presence,

made history.

With regard to the Author's, fine series of data, I find myself rather saturated

with statistics, indeed more than I can digest until given more time; but

I, think there is something further which deserves invesuganon and even

meditation, and that is what might be called the mechanico-physics

Journal No. 107

Unveiling of Memorial to Richard Trevithick, 17th May,

1932. 269-71.

In Camborne, Cornwall outside Public Library by H.R.H. Prince

George.

Sanford, D.W. (Paper No. 289).

The effect of commercial efficiency on locomotive design. 325-32. Disc.:

332-40. table

"Generally speaking, locomotive eng-ineers in this Country have bcen

less ready to introduce additional complications than have designers on the

Continent and in America, where many of their. engines resemble Christmas

trees ladcn with every conceivable device. Haw we in this Country been right

in this attitu,de or can we be justly accused of being less progressive than

locomotive engineers in other countries?" Sanford regarded the following

as "additional complications":

- abnormally high pressures or very high. superheat

- more cylinders than the minimum necessary to give the required power, within the limits of the loading gauge

- poppet or other special forms of valve gear

- superheaters for local or shunting engines

- ball or roller bearings

- mechanical lubrication to cylinders or axleboxes and motion

- alloy steels or light alloys for motion. parts

- alloy stee1s for boilers

- feed-water heaters, ranging from the exhaust steam injector, as the most simple type, to the most complicated type with steam pumps, storage drums for hot water, etc.

- automatic stokers

- pulverised fuel burning apparatus

- boosters on engine or tender

- thermic syphons.

H. Chambers (332-3) commented on the above:

-

Roller Bcarings: in America a locomotive is in service which is fitted with roller bearings for axleboxes and motion parts. So far as the L.M.S. is concerned, tests have been carried out on a train fitted with roller bearings and compared with a similar train with plain bearings; there was a definite saving of fuel in favour of roller bearings and the question of this saving being a commercial proposition wiIl be fully considered. Our friends from the running department would no doubt welcome roller bearings for locomotives, but so far as we know at present the cost is practically prohibitive.

-

High Boiler pressures.-The general tendency appears .to be to increase boiler pressure, although there is a strong feeling that with the conventional type of firebox high pressures wiIl lead to heavy boiler maintenance costs.

-

Mechanical Lubrication: On the LMS there were.1200 to 1500 locomotives fitted with mechanical lubrication. This has been the result of careful investigation, and he considered that any fitting applied on locomotives to relieve enginemen was well worth consideration

-

Feed-Water Heaters.-This question is very debatable, and generally in Britain feed-water heaters have not been favoured; on the other hand, exhaust steam injectors, which is a comparatively cheap and simple fitting to apply, almost a standard fitting for main line locomotives. It should be remembered, however, that with feed-water heaters another source of benefit is obtained and is an important one, I refer to the effect of temporary hardness being removed before the water enters the boiler and so ensures a better and cleaner condition of the boiler.

-

Automatic Stokers.-Such a fitting cannot be justified unless the grate area is beyond human firing; the main claim that can be made, therefore, is labour-saving, and obviates the necessity of opening firebox doors, which helps maintaining a constant firebox temperature, but no claim is made for fuel economy.

-

Pulverised Fuel-One would think that this would be an immediate success on locomotives, but in this country coal is produced, and due to the high cost of the locomotive equipment and accessories it is not a commercial proposition. In Germany (where pulverised fuel has been

Creighton, T.G. (Paper No. 290).

The training of apprentices on Indian State Railways. 344-57. Disc.: 358-78.

General meeting of Indian and Eastern Centre held in Calcutta on 25

July 193f: chair occupied by S.N. Flatt

The Indian State Railway Workshops Commission in 1926, under Sir Vincent

Raven and J.M.D. Wrench marked a turning point in the profession of Railway

Mechanical Engineering in India. Although the Commission confined its activities

and recommendations to the modernisation of systems, methods, equipment,

layout and management of workshops, yet the impetus it gave to the profession

in general was reflected in other important directions such as the

standardisation of design, labour, etc.

Casilla, pseudonym

Locomotive cabs. 379-85. Disc.: 385-6.

Fourth Quarterly Meeting of the South American Centre (1931 Session)

held in Buenos Aires on Friday, 18 December 1931 with J.G. Maylie as chairman.

Cab Construction: To reduce maintenance costs to a minimum, the

construction should be of steel having a double roof with steel distance

pieces to keep the plates apart. Tender locomotives require a protector plate

at the cab back and this should be provided with drop windows to allow for

ventilation of the cab during the summer months. Sliding windows or shutters

at the cab sides and sliding doors. Platform. The coaling or shovelling

plate on both tenders and bunkers should be preferably on the same level

as the bottom of the fire-hole so that the fireman has neither to raise nor

lower the shovel while firing. The wood platform on tank locomotives requires

a steel plate recessed into the wood and immediately below the bunker door

to facilitate shovelling any coal that has fallen to the platform. Cab

Windows should be arranged so a driver of aberage height can get a good

range of vision without having to put his head outside the cab. The front

windows should be of the swivel pattern. Tool Boxes: built-in type

preferable. Boiler Mountings: all steam valves should be mounted

on a steam turret on the firebox top in front of the cab front plate and

with the control wheels only inside the cab.

Journal No. 108

McDermid, W.F. (Paper 291)

The locomotive blastpipe and chimney. Part 1. 397-427. Discussion. 428-46.

Seventh Ordinary General Meeting of the Session 1931-32 held in

conjunction with the Twenty-first Annual General Meeting in the hall of the

Institution of Mechanical Engineers, Storey's Gate, Westminster, on Thursday

31 March 1932, at 6.20 p.m. The chair was occupied by J. Clayton.

It is well known that the successful running of a locomotive largely depends

on the draught through the furnace, and that correct co-relation between

blast-pipe and chimney is of vital importance to the production of this draught;

efficiency, however, does nof demand the strongest possible draught, it being

quite easy to get too much and thereby suffer a loss.

In the matter of raising steam, which, of course, is the ultimate aim, draught

is merely one factor amongst many to be allowed for, such, for instance,

as furnace and flue efficiency, thus it would appear that locomotive blast-pipes

and chimneys cannot be adequately discussed apart from these other contributing

factors, most of which will be reviewed in more or less detail in the

Paper.

In presenting a Paper such as the present one, it is usual to refer to past

experience and example, so that progress at each period may be noted afresh,

and modern methods be brought into true perspective ; moreover, there is

always the chance that an early device may suggest the solution of a modern

problem.

After devoting a considerable time to searching amongst early records at

the Patent Office and elsewhere, with a view to finding out who first use,d

a blast-pipe in the chimney of a locomotive, the Author very much regrets

his inability to state with certainty who it was.

Brief History.

Apparently the first reference to the subject of locomotive draught production

was made in 1805, in a letter addressed to one William Nicholson, of Soho

Square, London, the editor of a scientific journal. In this letter one Davies

Giddy reported on a special test which had been made with a locomotive built

by Trevithick, and said:—

"The fire brightened each time the steam obtained admission into the chimney

as the engine made its stroke."

Obviously Trevithick's exhaust had some blower effect on the fire, It does

not follow, however, that he used a jet-blast in the chimney, but the minds

of those who attended the test must have been inceptively impressed with

that idea by the results obtained. At any rate, William Nicholson appears

to have been so impressed because, during the following year, he obtained

a patent for a steam-jet blowing apparatus. In Nicholson's device the steam-jet

was used to entrain atmospheric air and force it through a coned hole formed

in the side of a reservoir. The air pressure maintained in the reservoir

was sufficient to supply air for a blast furnace.

Nicholson's specification illustrates his invention as for use in the horizontal

plane, but if placed in the vertical plane, as now reproduced for the purposes

of this Paper it closely resembles a modern locomotive chimney and blast-pipe,

in that, not only has the blast- pipe a contracted orifice, but the chimney

portion of the apparatus has a decided waist at the junction of

convergent-divergent cones.

The text of Nicholson'q Specification runs as follows:—

(a) represents a pipe through which the stesni passes out from the boiler

or other apparatus, whence it proceeds through the tube or pipe (d d)

carryingalong with it a large portion of common air, which enters through

the side spaces (b b ) , and this mixed fluid mass passes thejice through

(c c); . . . the aperture of (a) must be of such a size as shall be best

adopted to the intended emission of steam of such elasticity and temperature

as may be best suited to the objects in view; and so likewise must be the

diameters, from, and relative situation or distance of, the pipe or The apparatus

disclosed by Nicholson performed a duty mechanically equivalent to the duty

of a modern blast-pipe and chimney, but he made no mention of locomotive

requirements (possibly this was because he thought that the steam locomotive,

which was just born, would be of little consequence). He did, however, mention

the entrainment of vapour or smoke by means of his devices; therefore, had

modern locomotives arrived soon after the year 1806, Nicholson would have

been entitled to collect royalties for the use of the blast-pipe.

In 1813, or about seven years after Nicholson’s effort, William Hedley,

of Wylam, Northumberland, built a locomotive in which the exhaust passed

into the chimney in such a manner that its action earned for the engine the

name Puffing Billy.

When making reference to this event, Professor Andrew Jamieson, of Glasgow,

definitely states :-

“ It was Hedley who first turned the exhaust pipe up the chimney and

contracted its end, in order to intensify the draught in the fire and flues.

”

This statement was perhaps inspired by a letter dated September, 1854, n6w

in the Science Museum, South Kensington, and affixed to Puffing Billy,

which letter confirms the fact that Hedley did turn the steam blast into

the chimney, but when Hedley wrote a letter in 1836,‘ asserting his

claim to various improvements in the locomotive engine, it is a very significant

fact that he did not mention the blast-pipe as one of them, especially as

by that time the value of the invention was well known.

Of course, Hedley may have used a blast-pipe, because in 1806 Nicholson’s

specification mentioned that the principles of its action were well known

to men of science, who referred to its effects as “ the lateral action

of fluids,” moreover, fitting an intermediate chambcr to act as a silencer

for the exhaust, which Hedley did, suggests that his blast was sharp; but

if he dbd in fact use a blast-pipe, it is remarkable that his neighbour,

George Stephenson, who must often have watched Hedley’s engine at work,

was not sufficiently impressed by the blast effects to adopt the device for

his own locomotive until sixteen years after the birth of Puffing

Billy.

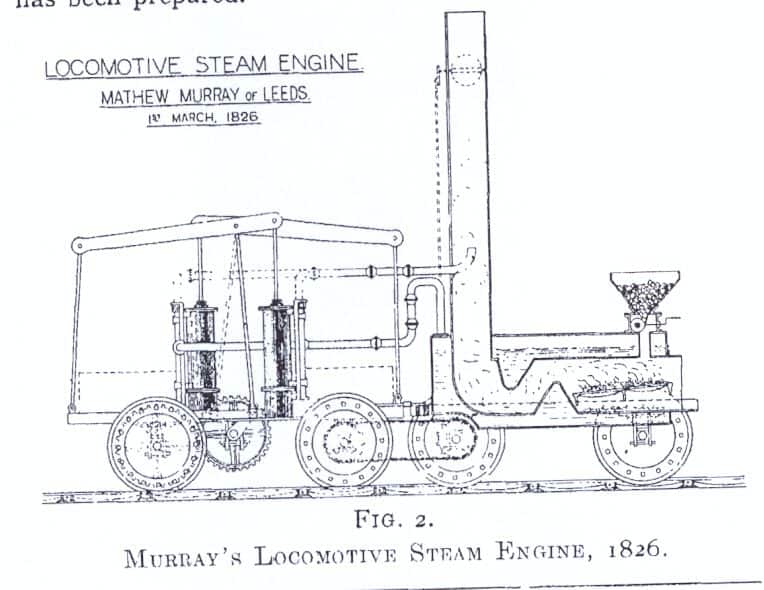

On 1 March 1826, there appeared in Newton’s London Journal,”5

as part of an original communication to that paper, an illustrated proposal

for an improved rail locomotive.

The design therein illustrated, which is attributed to Mathew Murray, of

Leeds, shows a blast-pipe located in the centre of the chimney. The pipe

is open-ended, that is to say, it is not contracted at the orifice. So far

as the Author is aware, this is the earliest record of a blast-pipe appliemd

to a locomotive and placed co-axial with the chimney.

|

There is no record of this locomotive in the patent files, and probably no

such locomotive was ever built. From a photostat of the original illustration,

Fig. 2 has been preparad. Observe not only the blast-pipe and its flexible

connections, but an articulated locomotive, with geared drive, with pulverised

fuel, hopper fed ; the self-trimming grate and the damper control arranged

at the outgoing end of the flues.

In 1828, Nathan Gouch, of Salford, illustrated in a

patent specification, a parallel exhaust pipe located in the centre of the

chimney ol a steam driven road coach. Gouch did not suggest this pipe as

intended to create a draught, however, but only as a means for disposing

of the waste steam ; therefore, in the Author’s opinion, Gouch cannot

rank as a blast-pipe inventor even though it may be that he was the first

to shsw one in a patent specification. In 1829, when Stephenson’s

Rocket won the locomotive competition at Rainhill, the exhaust from

the engine was directed up the chimney to maintain a draught. it is said

that the Rocket arrived at Rainhill, for a preliminary trial and display,

fitted with two exhaust connections at the sides of the chimney entering

in such a manner that no blast effect was produced, and that during the trials

it became apparent to Stephenson that Timothy Hackworth’s locomotive,

which had the exhaust directed up the chimney, was the best steam producer

while running.

Hurried alterations were then made to the Rocket, over-night, and

she ran the official trial with her two exhaust jets turned up the chimney,

each jet having a contracted orifice 1½ inches in diameter. The foregoing

allegation is supported by a footnote in the Minutes of Proceedings, Institution

of Civil Engineers, Volume CXXXIII, page 262, which reads as follols:-

Mr. Edward Woods, Past-President, Inst. C.C., on going to thc Liverpool and

Manchester Railway in 1834, was informed by Mr. John Melling, the Locomotive

Superintendent, that at the time of the Liverpool Competition in 1829, and

in consequence of the great advantage found in the blast-pipe of

Hackworth’s engine, he, before the trial took place, and working almost

night and day, constructed and inserted a regular blast-pipe into the chimney

of the Rocket and thus greatly increased its steaming power.”

It appears that at Shildon, in 1827, Timothy Hackworth, the locomotive

superintendent of the Stockton and Darlington Railway, had actually fitted

a true blast-pipe, with a contracted orifice, to one of the company’s

engines, the Royal George ; but it was not until after the famous

trial had been won by an observant rival, who used an equivalent device,

that the invention became generally known and was referred to as the blast-pipe.

Stated briefly, the Author is of the opinion that William Nicholson invented

the blast-pipe in 1806, that 20 years later Mathew Murray suggested its

application to a locomotile, and that twe1ve months after that, or in 1827,

Timothy Hackworth actually fitted the invention on the Royal

George.

Fig. 4 shows a comparison of Hacknorth’s and Stephenson’s

blast-pipes.

Neither the Royal George nor any other locomotive built during the

next sexeral years, had a chimney shaped to assist a streamline flow of the

gases, despite the fact that Nicholson had pointed the way to this desirable

feature at his first attempt. Early locomotives had a blastpipe carried well

into the chimney, but adjustments to secure better results gradually brought

the blast orifice lower and lower until, by about 1850-60, the orifice was

roughly level with the top row of boiler tubes, or in much the same position

as in many of the engines of to-day.

The air required to be moved by the blast does not all pass through the fire.

Certain volatile hydrocarbons are released as the coal warms up, and these

valuable combustibles would pass away through the flues unburned, if it were

not for a secondary supply of air which is arranged for above the fire.

As early as 1841 special devices were brought into use to act as ducts for

this secondary air supply, such, for instance, as hollow firebox stays, or

open-ended tubes passed through the shokebox, water space and firebox tubeplate,

to deliver air, which had been pre-heated by smokebox gases at suitable points

abwe the lelel of the fire. In some cases the air was forced in by steam

jets, so that its higher velocity might assist in making a more intimate

mixture of hydrocarbons and air, to promote complete combustion. Not much

is heard of these devices today, perhaps they were introduced before their

time, or it may be that, at the period of their testing coal was too cheap

to bother about; but, whatever the reason for the delay, the question of

their utility is not yet settled, because a recent engine of note has a

pre-heated air supply arranged for. Speaking generally, however, on a modern

locomotive the supply of secondary air is taken in at the firehole. It is

evident that in about 1860 the question of draught efficiency received a

lot of attention. The inclined brick arch in the firebox and the deflector

plate in the firehole were introduced at that time, and chimneys resembling

an inverted cone, or having a belled entrance below the. waist were tried,

sometimes in association with multiple petticoats extending well into the

smokebox and designed to distribute the effects of the blast over the whole

tube area. At about this time also, the ring blower was introduced to maintain

the draught when exhaust steam was not available for the purpose.

Proportions for blast-pipes and chimneys are often arrived at experimentally,

to suit the requirements of a given locomotive, and many such experiments

have been made; but, except when all the steam raising factors have been

allowed for, very probably the result has been a thermal loss due to too

much draught.

Draught efficiency is ordinarily measured only by the degree of vacuum intensity

in the smokebox, but, of course, the weight of steam raised per pound of

fuel, to nieet the varying demands made on the engine, is the real efficiency

measure for the draught.

Present Objective.

The object of this Paper is to review the published findings of many of the

experimenters, to place on record any factors which influence the raising

of steam and are susceptible of draught variation, and also to adalyse in

detail each identified factor and its incidence on draught maintenhance Due

to the interdependence of the several parts of the draught apparatus, there

was some overlapping or blending of their functions, but the subject was

reviewed under the following main headings:

- Ashpans and dampers.

- Movement of air at normal temperatures.

- Air openings through the grate.

- Fire thickness and draught intensity.

- Specific heat values for the gases of combustion

- Importance of high temperature in the firebox.

- Handling the gases of combustion.

- Natural draught and forced draught.

- Blast-pipe duty. The Smokebox. The Chimney.

Ashpans and dampers.

Ashpans should be deep enough to permit ready access of air to the

whole grate, otherwise an even fire cannot be maintained. It is sometimes

necessary to prevent the passage of air to the underside of the grate, hence

ashpans are made practically airtight and fitted with dampers under the conrol

of the operator. By opening the leading and closing the trailing damper the

draught through the fire can be increased to the extent of the air pressure

at the leading end, which is due to the movement of the engine; or, on the

contrary, the draught can be eased by using only the trailing damper. A damper

opening 25%. of the grate area has been suggested as desirable, but many

locomotives have only about 12% provided, and Stroudley considered just under

7% sufficient. A 12% damper opening, serving a grate having air openings

provided which amount to 30% of the grate area, will produce rarefaction

in the ash pan to the extent of 0.3 inches of water, if the pressure difference

above and below a 12-inch fire on the grate is to be 4 inches of

water.

The movement of air.

Figure 8 showed the weight, volume,. and ve1ocity per period of

atmospheric air when impelled by any pressure difference up to about I7 inches

of water pressure. The graph covers the normal temperature range, 32°

to 92°F.; the velocity of flow at any other temperature, or pressure

difference in inches of water can be calculated by using the formula given

on the graph.

Air openings through the grate.

British locomotives have openings through the grate, for the passage

of air, amounting to about 30% of the grate area. French practice includes,

in some cases, air spaces amounting to about 45%. In America, some grates

are provided with only about 25%., while others have about 40% open. The

class of fuel used may, to some extent, account for these differences in

grate construction; but, other things being equal, theoretically the resistance

offered to the pas-

Noted that specific heat values for for coal had stil to be defined

authoritatively. A high tempertuare in the firebox is essential as this is

where 40% of the heat is taken up. The temperature at the entrance to the

tubes should be 2190F but is only 1800F. The ignition temperature of coal

is 700-925F. Jumper blast pipe mentioned on page 416. Notes Committee of

Railway Master Mechanics Association on Handling the gases of combustion.

7lb of steam is produced from 1lb of coal

Cited University of Illinois

Bulletins Nos 82 and 101. When

considering forced draught he considered the

Gresley paper on three-cylinder

high pressure locomotives presented to the Institution of Mechanical

Engineers, 1925-9-927 noting fluctuations in smokebox vacuum. Noted that experiments

had been conducted in the USA "about thirty years before" on blastpipes and

chimneys.

Page 427: Reproduced letter from Davies Giddy

to William Nicholson in London on the effect of exhaust steam through the

chimney on the fire on Trevithick's locomotive. This letter was published

in J. nat. Philos. Chem. Arts, 1805, Sept.

Discussion:

D.W. Sanford (428-9) noted that a front damper caused

the draught under the grate to be increased, whereas a back damper tended

to impair the draught; and questionned whether use of the front damper, and

if this creates too much draught, then to bore out the blast-pipe and reduce

the back pressure on the pistons? Why is it that on certain lines the practice

of running the back damper is adopted? Regarding the chart showing the

temperature of the gas entering the tubes and the temperature of the gas

leaving the tubes at the other end, he questionned whether they were calculated

temperatures, or whetncr they were observed by some form of pyrometer? McDermid

noted that they were calculated. Sanford asked if according Lawford Fry's

formula? and then made observations on the proportion of the chimney diameter

to the blast-pipe: if we take the figure of 24½ pounds of products of

combustion, to one pound of coal burnt, and if we assume the ordinary

temperatures for the gases and steam coming away from the cylinders, he

considered that the area of the chimney should be roughly nine times the

area of the blast-pipe, irrespective of the quantity of steam which is passing

up the blast-pipe — that is to say, whether the engine is working heavily

or lightly — and that means to say that the diameter of the chimney,

in their experience, had to be roughly three times the diameter of the

blast-pipe. He wondered whether the Author agreed with those proportions,

which were found satisfactory There is a rule given later on proportioning

blast-pipe diameter on the grate area. The rather curious thing is that we

have got chimneys and blast-pipes of the same diameter, some of them on main

line engines which may be doing anything up to 1,200 horse-power, and we

have got the same size chimney and blast-pipe on little shunting engines

which probably never do more than about 400 horse-power, and they work quite

satisfactorily in both cases, though I admit that on the bigger engines everybody

would like to get a bigger chimney if possible.

Sanford described a "rather interesting case a little time back" where

they linered down the cylinders of an engine, for a special experiment, so

that the cylinder volume was reduced to almost exactly half what it had been

before the liners were put in, and they had sufficient confidence in their

ideas about blastpipes and chimneys to do nothing whatever to the blastpipe

or the chimney-that is to say, this engine, which was made half its original

capacity, went out with the same blast-pipe and chimney, and it steamed perfectly

satisfactorily, which seems to show that the blast-pipe orifice has nothing

to do with the size of the cylinder, and seems to depend on the size of the

chimney. As regards the method of fixing the relative position of the chimney

and blast-pipe orifice, one quite satisfactory method is to draw lines from

the inside bore of the blast-pipe orifice to the inside of the chimney at

the top, and so arrange the relative positions that the angle between these

two lines has a definite value.

That is one method of fixing the relative position, and that is what

stops you getting a big enough chimney, because if you want to get a big

chimney, it means that your blastpipe cap, to keep the correct angle, gets

so low that it would be buried in ashes, I wonder whether the Author agrees

with this method of keeping the angle constant, and what angle, in his

experience, is the best. If, of course, we could get a bigger chimney we

should turn out the products of combustion at a lower velocity, and therefore

saye some of the kinetic energy which we now throwaway.

Sanford on main line engines you may throwaway 50 or 60 horse-power in kinetic energy, which means quite a lot going to waste. I wonder whether the Author will teII us his opinion of a very ingenious device which is being used in Belgium just now—that is, the double chimney and the double blast-pipe, because if you cannot get one big chimney you can get the same thing by putting in two little ones, stilI keeping the same angle and the same ratio between each individual blast-pipe and its individual chimney, under 'which, of course, it is correctly set. Another old friend which was at one time thought a lot of is the Adams vortex. There again you increase the outside diameter of a blastpipe cap by putting up an annular space in the middle, which would enable you to get a bigger chimney, and you cou1d also increase the area of the jet and alIow it to entrain some more gases up the middle and the outside surface. Can the Author tell us why this type, which was so highly thought of at one time, has now fallen out of use? Is it because with the bigger engines you have not got room to put the air passages in?

In reply to Sanford, McDermid did not know, but had been told, that if one leaves the front damper wide open travelling at speed one will get large holes through the fire, and that explains why so many locomotive operators prefer to use the back damper. In America, for instance, where sometimes there is a lot of snow they have to depend on the back damper otherwise they may get the ashpan full of snow. With regard to proportions of blast-pipe and chimney it seemed to McDermid that these two items must naturally be correlated in the matter of areas of opening. Acting together, they form a jet instrument the parts of which must necessarily be made to some relative proportion and be placed at a distance apart conforming with some law, not yet defined. With regard to the angle made by the steam jet, he had had no personal experience. Mr. Gresley, however, when discussing the matter some years ago, told him that he thought Mr. Hughes made some experiments with a window in the front of the smokebox, and he found that the natural angle of the steam jet was a cone tapering about one in six. That statement is more or less confirmed by illustrations seen recently in Professor Goss's books. The steam jet appears to be merely an inverted cone with a taper of about one in six on the diameter. What the angle is in degrees he did not know. Mr. Sanford, and others, mentioned the Adams vortex blast-pipe: he considered the Adams blast-pipe was also an ash ejector. More recent example of much the same sort of thing, included 'Stone's blast-pipe, in which a petticoat around the blast-pipe came down to near the bottom of the smokebox and cleared the ash out by blast action.

H. Chambers (429-30): noted Sanford's mention of the Adams type Vortex blast-pipe, . My recollection of that blast-pipe is that there were two side openings provided low down on the blast-pipe by means of which the lower boiler tubes would get a fair share of draught, and then give, a uniform draught over the whole tube area. With regard to the vanous types of blast-pIpes that have be used with varying success, I remember on the old London-Tilbury engines there was provided in the blast-pipe orifice a double inverted cone which was hollow. That cone was filled with common salt. The position of the cone controlled by means of a centre spindle which ran down through the bottom of the blast-pipe, and was connected through a bell crank to the reversing shaft and was therefore automatically controlled by the notch position so arranged that the best orifice was provided for steaming purposes. That, I may say, has been long defunct, and the normal type of blast-pipe cap is now used. I also remember those years ago a driver never went out without a bucket hanging or wire to fit across the blast-pipe cap to improve steaming. That, of course, was not recognised officially, but it is interesting bearing in mind that the Author mentioned the provision of a bar which had the effect of cutting the blast and increasing the periphery for engaging with the products of combustion passing into the chimney. It must be remembered, however, that any alteration made to sharpening the blast may, if other factors are neglected, adversely affect the coal consumption.

There is one point with regard to chimneys in which I have been very interested, and I think all will appreciated when I mention that on the various railway companies' locomotives the position of the chimney with relation to the smokebox tube plate varies very considerably. My expereience has been that it is desirable to keep the chimney and the blast-pipe position well back. When I. say well back, I mean within the limits allowed by the design of the modern locomotive smokebox. The theory I have always had in mind is that the products of combustion escape from .the tubes at a very high velocity and they pass by the blast-pipe before they are fully under the influence of the escaping blast of steam up the chimney and thereby the sparks which are carried forward strike the front of the smokebox door and drop into the bottom of the smokebox and in effect is a very efficient spark arrestor. On the other hand, locomotives in many cases have the chimney fitted well forward from the smokebox tube-plate. I would hke to ask the Author whether in the course of his investigations he has found any marked influence on the efficient steaming of the engine.

H. Holcroft (431-3): Like many others, I have looked forward to hearing this Paper very much indeed. The blast-pipe and chimney together form one of the most important parts the locomotive, which comprises two distinct units — the boiler, complete with the smokebox, ashpan, and so on, and the engine part with the cylinders, motion, frames and wheels. There is no connection whatever between these two units, except the jet of steam which escapes from the cylinders, through the blast pipe, and that is the one connection between the two that makes the locomotive a single unit and everything depends on the efficiency of the apparatus through which that exhaust jet passes. For intance, an engine may have a very high tractive effort, but unless the boiler generates enough steam it cannot sustain a high tractive effort when running. On the other hand, if there is plenty of steam, it may be that through excessive back pressure the locomotive cannot develop its full horse-power, due to choking by a restricted blast-pipe orifice to get the necessary draughts.

With regard to ash pan and damper openings, Mr. Sanford called attention to the question of the use of front and back dampers, the idea being..that when the front dampers open an inrush of air is obtained which assists in the draught. I have tried on many occasions, with different locomotives, the effect of changing from front to back opening while running, and vice versa, but have never detected the slightest influence on the draught; as far as I can see, it does not make any difference at all. On the other hand, when running through a tunnel or a long, low bridge with only a small regulator opening it often happens that a sudden tongue of flame shoots out of the fire-hole, simply because the air is confined and there is no lateral spread of the air under the engine; it cannot get away, with the result that a sudden increase of pressure occurs in front of the ashpan and the air rushes in; but apparently in the ordinary course of running the air is dragged along with the locomotive, or projected out sideways, so that this increase of pressure that the Author rather relies on does not materialise in practice. .

Regarding air openings through the grate and fuel bed, Holcroft observed during one of the coal strikes when American coal of rather lower calorific value than the ordinary English was used, that the steaming was nevertheless very good. The reason attributed to this was that the screened coal was of more or less uniform size; hence the openings through the fuel were regular, and very much nearer to the ideal conditions for combustion. With a screened coal about the size road metal, combustion seems very efficient.

Holcroft's experience indicated that locomotives with oval or approximately oblong firehole doors are much better steamers than those with round openigs: with round fireholes and half-round deflectors there is a much greater bunching of cold air, which reaches the tubes in the middle of the tube plate. In the case of a wider and less deep opening with a more less level top the air gets spread out better. A device which firemen can often make a shy steaming engine steam well, is that of putting a piece of plate across the lower part of a round fire-hole and firing over the top of it. Apparently the air, in striking the sharp edge of the plate, is deflect downwards on to the fire instead of going direct towards the tube plate.

The position of the chimney on the smokebox had been referred to by Mr. Chambers, but it has been Holcroft's experience that it is better to situate the chimney well forward, because it brings about a better distribution the draught over the front tube plate and the gases do not have to take such an abrupt turn to reach the vertical. On the question of nibs, bars, corrugations, etc., near the blast-pipe orifice, to produce eddying and so entrain more gas, it is doubtful whether this is really anadvantageous because the result is to increase the contact area of the steam with the solid surfaces, and so reduce its velocity. Also there is the question of the carbonisation of the blast-pipe which becomes furred up with carbon deposit in a very short time, and this collects under any projections in the orifice: that was one of the reasons for the Adams vortex pipe being abandoned — the difficulty of removing the carbon deposit from the narrow annular orifice.

As regards the action of the exhaust steam in producing draught, nobody seems to have come to a definite conclusion as to what really takes place, but apparently several actions occur; there is a certain amount of ejector action due to surface contact of high velocity steam with .the gases, a small amount of entraining of the gases, and to some extent, perhaps, a piston-like action of plugs of steam in the chimney with each exhaust beat which sandwich the gases between them; and so it seems to be a mixture of those three in varying proportions. Another thing about the blast-pipe is that it is always assumed that the steam comes out of the blast orifice at equal pressure all over, but I was very much struck when travelling on the leading engine of a pair going through a long tunnel on an up-grade, in watching the sparks coming from the chimney of the second engine, which as an old saturated engine with the steam-chest between the cylinders. As the sparks came out they made a different angle of incidence with the sloping tunnel roof with each of the four beats in a perfectly rhythmical manner, showing hat the direction of the steam and gases took a slight change with each beat, and I put that down to the fact that possibly the direction from which the steam came from he cylinders made a difference. Perhaps through being a saturated engine a certain amount of moisture came up with the steam, and was projected to one side, and it evaporated at or near the blast-pipe orifice where pressure changed to velocity, so that there was a difference of density n the blast-pipe orifice itself which deflected the jet slightly. That may be an explanation as to why an engine with its valves badly out of beat is often a bad steamer, because the effect of the blast is more pronounced in one direction than another, and thus have the same effect as if the chimney and blast pipe were out of line.

Colonel Kitson Clark: (433-4) I have not very much to add, except one or two historical points. One is the story about he blast-pipe in the Rocket. I believe that the father of our friend Sir John Dewrance also worked on that blast-pipe.He might, as there was a record passed to Sir John many years ago as to his father's connection with the story. With regard to what Mr. Holcroft said about the oval fire-hole door, I had the privilege of riding on the top of the boiler of an Atlantic type locomotive that ran from Philaelphia to Atlantic City in 1897. The firebox, as far as I remember, was styled Wootten. It had two fireholes, and the coal was exactly what has been described-picked pieces, rather smaller than one's fist, over the whole of the grate area, and they practically did not add any fuel during any time of the run of 47½ miles. The, engine steamed extra~ordiriarily well, and perhaps rather from its own merits than my approving presence, made history. With regard to the Author's fine series of data, I find myself rather saturated with statistics, indeed more than I can digest until given more time; but I think there is something further which deserves investigation and even meditation, and that is what might be called the mechanico-physics.Mr. Chambers raised an interesting point about the - position of the chimney. He is quite right, if the chimney is well back, sparks go into the front end of the smokebox and die before they go through the chimney, but so far as the position of the chimney is concerned in the matter of forming a draught, I cannot conceive that its location makes ny difference at all except as Mr. Holcroft has said, the gases take an easier bend to the exit when the chimney is laced well forward. One may regard a smokebox as a chamber which is exhausted by the action of the blast, and though I.do not pretend to speak with any authority on it the subject, I think that most of the troubles are really due to too much draught. For instance, Mr. Carling was talking about a 50 per cent. improvement effected by altering the blast, one wondered what the draught arrangement was before the alteration.

Mr. WiIIiams mentioned the Garratt locomotive. I would like to ask him this, just by way of collected iriformation. In the Garratt locomotive there is one very long blast connection and one short one. Is there any noticeable difference in the fire, due to the reservoir capacity - in the long blast-pipe? It would appear that there must be a cushioning of the blast, which should give all the gentle draught advantages of, for instance, the Kylala blast pipe, which, owing to a large exhaust opening, gives a more a gentle jet effect. The figures which I have put before all tend to prove that a gentle zephyr through the fire gives the best and most economical results.

With regard to the position of the fire-hole in relation to the deflector, plate and the shape of the firehole Mr. Holcroft mentioned the fireman's trick of blocking the lower half of the fire-hole to secure better steaming. The fireman's device made a more effective deflector' plate, and this means that he drove air straight down on to the fire, which is just what is wanted. Drive the air entering the fire-hole straight down on to the fire it will get hot and thus improve the temperature of the firebox. Keep up the temperature of the firebox and you will get good results.

Mr. Carling said that the blast-pipe on a certain locomotive was altered to advantage, but he did not say whether they increased the draught or reduced it. - May I ask whether you increased the draught or reduced it? Mr. D. R. Carling: I have only got down the evaporation figures on my notes. I think, however, that the

D. Kitson Clark (433-4) referred to the blastpipe and draughting

arrangements for the Kitson-Still locomotive. D.R. Carling

(434-6) noted that one of a highly successful series of 2-8-2s built

for the Missouri Pacific Railroad had been rebuilt as a three-cylinder

locomotive. This locomotive was tested by the Pennsylvania Railroad at Altoona

and modifications made to the blastpipe enabled an increase in the maximum

evapourative rate from 48,000 lbs/h to in excess of 60,000 lbs/h and this

emphasised the potential available through improved draughting. He added

that Duplex chimneys require further examination. Cited Ulrich Barake:

Rechernische Untersuchung der Warmeuberttragung im Lokomotiv-Langkessel.

Author (page 436) noted that Hughes experimented with a window into the smokebox

and discovered that the steam jet from the cone tapered at about 1 in 6 and

this is similar to that stated in Goss's books. He noted that the Adams'

Vortex was also an ash ejector as was Stone's device. He asked Williams if

the distance from the firebox affected draughting on Garratt locomotives.

Seventh Ordinary General Meeting of the North Eastern Centre (Session

1931-32) held in the Hotel Metropole, Leeds on Friday 8 April 1932 at

7.15 p.m.: chair taken by T.H. Sanders, Chairman.

Saunders (439) noted that the Vortex and Maclellan variable blastpipes had

been used on the GER. (in response McDermid noted that the Maclellan blastpipe

had been standard on the GER for a time. W.E. Selby (439-40) was informed

by McDermid that the space between the firebars should be as large as possible.

J. Blundell (441-2) stated that the GCR had evaluated Hill's grate in which

steam was blown through the ashpan, but it was not very successful. Blundell

also returned to Gresley's paper on

three-cylinder high pressure locomotives to consider what was happening

in the smokebox. O. Becker (444-5) mentioned a considerable body of work

on the subject: in 1894 in Hanover there were experiments on nozzles, distances

and cylinder pressures; in 1901 the Master Mechanics' Association sponsored

experiments on stacks at Purdue University under Professor Goss; and there

were tests performed at St. Louis for the Pennsylvania Railroad. Sheridan

(445-6) noted that larger grate areas were common in Belgiium.

Brazener, W.F. (Paper 293)

The manufacture of copper firebox plates. 447-74. Disc.: 474-500: 1934,

24, 128-41.

Eighth Ordinary General Meeting of the Session 1931-32 held in the

hall of the Institution of Mechanical Engineers, Storey's Gate, Westminster

on Thursdav 21 April 1932 at 6.0 p.m. with chair taken by W.A. Lelean,

President-Elect.

Outlines principal properties of copper. Chronicles use of copper in the

manufacture of firebox plates. Details production of copper plates, covering:

casting, or ingots. The chief cause of trouble in a firebox is due to the

wastage of stay heads and the portions of the copper plate near to the stay

heads on account of corrosion. This is found to be due to very small leakages

which occur when the firebox is cooled down, between the threads of the stay

rod and plate. The immediate effect of this is to remove the protective scale

on the stay head and the adjoining part of the plate. It is felt, therefore,

that if some method can be employed for producing a perfectly water-tight

seal at the stay head, the main cause of the trouble will be overcome.

Summer meeting, 23rd and 24th June, 1932. 501-4.

Due to the financial situation the usual bi-annual Summer Meeting

on the Continent was replaced by a two-day visit to Doncaster, Sheffield

and Derby organized by L.J. Leclair and H.E. Geer. London members, with the

President (W.A. Lelean), travelled on the 10.10 a.m. King’s Cross to

Doncaster in reserved compartments. On arrival they were met by R.A. Thom,

Mechanical Engineer (Doncaster), F.H. Eggleshaw, Locomotive Works Manager,

and W.H. Brown, Carriage and Wagon Works Manager, and under their guidance

were shown round the Locomotive and Carriage Works. On leaving the locomotive

shops the members were photographed (reproduccd) in front of one or the 2-8-0

three-cylinder goods locomotives incorrect: Gresley Pacific with corridor

tender). On view in the yard was one 0-8-4 tank engines recently fitted with

a reversible booster. The next visit was to Metropolitan-Vickers Electrical

Co.'s Attercliffe Works at Sheffield, and members travelled on the 17.24

to Sheffield. Having deposited their bags at the Victoria Hotel they proceeded

by motor coach to the Attercliffe Works. Here, under the guidance of G.H.