THE BRITISH OVERSEAS RAILWAYS HISTORICAL TRUST

|  |

Kevin Jones' Steam Index

|

|

Picture left shows Duke of Gloucester with

E.R.

Brown, F. Harrison,

R.A. Riddles,

J.W. Watkins,

R.C. Bond,

I.C. Forsyth and Cox.

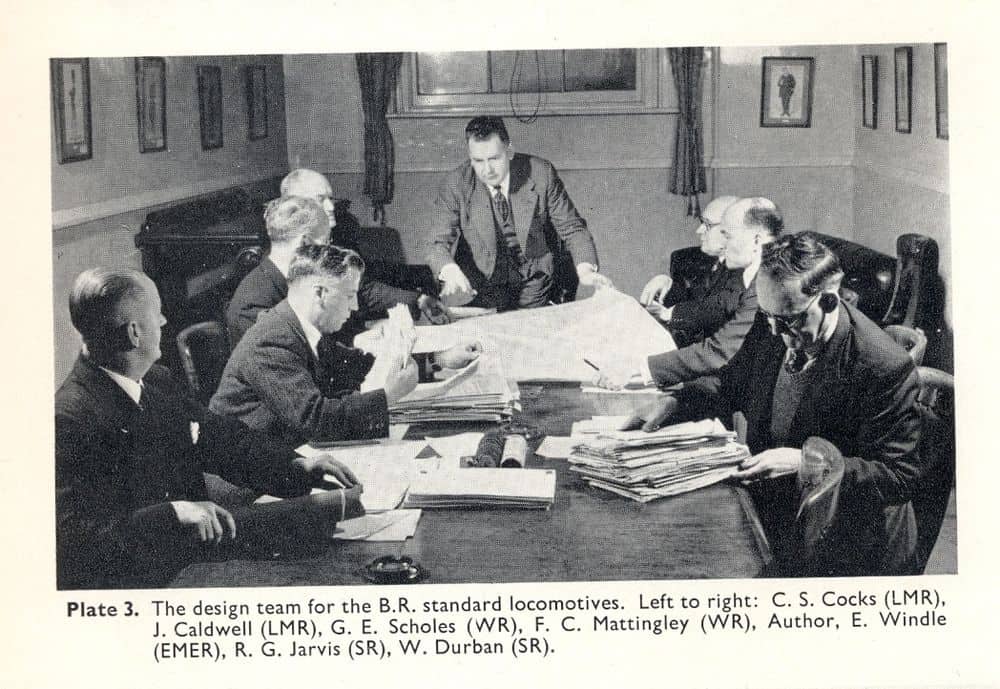

Picture right shows Cox with the design team for the Camel class: note

W. Durban on extreme right of picture, about whom KPJ

has still to trace anything. Others (l-r):

C.S. Cocks, J. Caldwell,

G.E. Scholes,

F.C. Mattingley, Cox,

E. Windle, R.G.

Jarvis

Both from Loconotive panorama Volume 2

Born Glasgow 1900. Died Berkhamsted 14 September 1992. The final chapter of Chronicles of steam is autobiographical in terms of his earlier life: the other books give some details of the remainder. Marshall notes that he was educated at Merchant Taylors School, Crosby and was apprenticed under Hughes at Horwich Works. His books, sometimes criticised by Rutherford in Backtrack, remain one of the greatest insights into locomotive development on the LMS and (for steam) on British Railways. Only K.J. Cook and Holcroft offer comparable glimpses. Cox was highly critical of Fowler and Beames, yet was equally stubborn in his own views on three-cylinder design (of which he may have been an inept practitioner) and of things non-LMS. The page on E.L. Diamond probably tells us much about Cox, and is a warning for future historians. There is a danger that Cox's views may be reproduced unchallenged. Adrian Tester has given an extended critique of considerable importance..

The Locomotive Mag., 1955, 61, 105 published a synopsis of his career so far: Appointed Mechanical Engineer (Development) on the British Railways Central Staff in which capacity he will act as deputy to the Chief Mechanical Engineer. Cox was educated at the Merchant Taylors School, Crosby, and received his engineering training at the Horwich Works of the former Lancashire & Yorkshire Railway under George Hughes. After a period in the Drawing Office at Horwich and, after the formation of the L.M.S. Railway. at Derby, in 1927 he was placed in charge of the Dynamometer Car at the latter centre. In 1931 he moved to Euston as Technical Assistant, and in 1935 returned to Derby as Assistant Locomotive Works Superintendent. In 1938 he became Personal & Technical Assistant to the Chief Mechanical Engineer and in 1941 Chief Technical Assistant. On nationalisation Cox was appointed Executive Officer (Design), dealing with both locomotive and carriage and wagon work, under the R.E. Mlember for Mechanical & Electrical Engineering, which post he held up to the time of his present appointment. Cox is a member of the Institution of Mechanical Engineers, whose George Stephcnson Research Medal he holds. He also holds the Gold Medal of the Institution of Locomotive Engineers of which he is a Vice President. He is a Lt.-Colonel in the Engineer & Railway Staff Corps and is a member of the Control Committee of the LUR. Office of Research & Experiments. He visited India with the Pacific Locomotive Committee in 1938, and was member of a party sent by the L.M.S. and L.N .E. Railways to the U.S.A. in 1945 to report on motive power development.

On page 87 of Locomotive Panorma (Vol. 1) there is an interesting observation: "However, the old insularity was gradually dissolving and as part of the Royal Scot investigation I was sent, in November, on to the Southern Railway to ride the Lord Nelsons. It was now that I was able to meet Clayton and Holcroft who, sharing the same office at Waterloo, had so great an influence upon the trend of design on that region [sic]. Although these engines rode much better I am afraid that the expedition threw little light upon our own particular trouble." It was probably that Cox's own insularity was ending when he met people of the stature of Clayton, and possibly Holcroft who could be viewed as his equal, but had far greater experience. Thus future historians should take note of Cox's limitations, especially when he relates to the period outwith his own expertise. His remarks concerning Beames should be treated with caution. There is some evidence that he was careless in his citation of others: "E.W." Selby, for instance, rather than "F.W.". In this respect he is less reliable than Holcroft..

Perhaps the most damning evidence against the overall competence of Cox is that there appears to be no reference to Goss in any of his works (that is through examining the indexes to his books) and this may explain why boiler performance on some of the Stanier designs was far from satisfactory.

Broadbent (Backtrack, 2011, 25, 454 for autobiographical article written by Edward Talbot) states that Cox was very aloof..

J. Hadfield wrote in 1948 "We have come to expect a good deal from any paper associated with the name of E.S. Cox, and are certainly not disappointed in the present instance"

Kevin Jones has a particular affection for Locomotive Panorama and Bulleid's Master builders of steam as they arrived in time to influence his Steam locomotive development

Papers

Balancing of locomotive reciprocating parts.

J. Instn Loco. Eng 1942,

32, 2-37. Disc.:1943, 33, 218-36. 4 illus,, 11 diagrs.,

3 tables. (Paper 432).

British standard locomotives. J. Instn

Loco. Engrs, 1951, 41, 287-335. Disc.: 336-403 + 5 folding plates.

22 illus., 20 diagrs., 7 tables. (Paper No. 502).

Experiences with British Railways standard locomotives.

J. Instn Loco. Engrs, 1954,

44, 212-54. Disc.: 254-305. + folding plate. 4 illus., 31 diagrs.,

7 tables. (Paper No. 532).

Analysis of the performance of the locomotives in service and on

test: summation given at bottom of this page..

Locomotive axleboxes J. Instn Loco.

Engrs, 1944, 34, 275-317. Discussion: 317-40:1945, 35,

221-38:1946, 36, 171-6+ 3 folding plates. 21 diagrs., 8 tables. (Paper

No. 447).

Locomotive wheels, tyres and axles. J.

Instn Loco. Engrs, 1935, 25, 761-87. Disc.: 787-828: 1936, 26. 807-32. (Paper No. 346)

Later discussion took place in Buenos Aires

A modern locomotive

history: ten years' development on the L.M.S.- 1923 to 1932. J.Instn Loco.

Engrs, 1946, 36, 100-41. Disc.: 141-70; 275-6. 9 illus., 14 diagrs.,

(incl. 9 s. els.), 11 tables. (Paper No. 457).

See also Locomotive panorama Volume 1

The history of the Institution of Locomotive

Engineers — the ten years to the Golden Jubilee. J. Instn Loco.

Engrs., 1960, 50, 682-6.

The remainder of the Institution's history was covered by

Holcroft

The contribution to railway engineering made by two Institutions: I. Mech.

E. [and] I. Loco. E.: 1847—1911—1969. Rly Div. J., 1970,

1, 35-61.

Survey of the contribution made by the two institutions to recording

the activity of railway mechanical engineering, especially within the Institution

of Mechanical Engineers.. Cites major contributors of papers beginning with

J.E. McConnell and John Ramsbottom. Unfortunately, the papers are not cited

in sufficient detail to be requested via the limited bibliographical resources

available in Nelson's County. Nevertheless dates are cited, such as Webb's

1883 paper on Compound locomotive engines. The activities of the Institution

of Locomotive Engineers are also surveyed.

with others

Cox, E,S. and Johansen, F.C. Locomotive

frames.. J. Instn Loco. Engrs, 1948, 38, 81-115. Disc.:

115-96 + 2 folding plates. 28 illus., 17 diagrs. bibliograpy.

(Paper No. 473)

Includes diffuculties experienced with Royal Scot class.

Comment on other's papers

Kirkland, R.I. Locomotive boiler repairs in headquarters shops.

J. Instn Loco. Engrs., 1934,

24, 340-1. (Paper No. 321)

A certain amount is being heard of copper welding, and I believe that

in certain centres this is being pursued actively, although in others it

is only being carried out experimentally. It would appear that there are

places where this could be used with advantage if the process could be perfected,

such as welding up the bridges on a copper tube plate which have cracked,

or welding along the seams of an inner copper firebox in the same way as

the seams of an outer steel firebox are sometimes welded today. It would

be of interest if the Author could say what are the difficulties to be overcome

in this method of welding, and what is the present stage of development.

'The Author has said nothing as to the effect of boiler pressure on the repairs

to be carried out. It is generally stated that high pressure causes a greater

amount of repairs to be necessary than is the case with lower pressures.

It is understandable that the cost of such repairs should be higher, in that

if a half side has to be replaced it is of a greater thickness in the case

of a high pressure bdiler than in the case of a low pressure boiler, but

is the amount of wastage of plates and stay heads definitely greater in a

high pressure than in a low pressure boiler? By “high pressure”

I do not refer so much to extra high pressures. beyond 250lbs., as to a

comparison of, say, a 200lb. boiler with a boiler of 160lbs. or 175lbs. pressure.

One result of being in close contact with boiler repairs is that it makes

it possible to see in actual practice the effect ot certain points in design

about which there have been differences of opinion in the past. A case in

point is the smokebox tube plate. In many designs a tube plate of the angle-iron

type has been put in, rather than the drumhead type, which latter has the

advantage of assisting in the interchangeability of boilers between one class

and another. It has been stated that the drumhead plate is more likely to

give trouble in the root of the flange. Can the Author say if this is a fact,

and whether there is anything to choose between the two types of tube plate?

A similar case is the design of firehole doors, as to whether there is any

thing to choose between the solid ring type and the other type where the

two plates are flanged outwards and riveted together.

Lynes, L. and Simmons, A.W. Brake equipment and braking tests

of Southern Railway C.C. electric locomotive.

J. Instn Loco. Engrs., 1944, 34,

345-95.

Cox pointed out that an attempt had been made in the case described

to do something over and above what had usually been attempted in steam

practice-namely, to produce a locomotive which was capable of performing

every function which fell to the lot of a locomotive, and to provide on the

one vehicle braking equipment to suit all circumstances. It might be ignorance

on his part, but he could not understand why the brake equipment on the

locomotive was stated not to be available for use in connection with the

usual Westinghouse automatic brake system on Westinghouse-fitted trains.

He did not see what feature there was in the braking layout which rendered

that impossible. At the end of the Paper the Authors said they were unaware

whether similar steps, in the matter of starting trains very gradually, were

in use with steam-hauled trains. An example of that kind which might be cited

was that of the Garratt loconiotives which hauled loose-coupled freight trains

of something like 1300 tons between Toton and Brent. The trains were so long

that they sometimes covered portions of the line including several gradients,

and the method used by the drivers in such circumstances was the extreme

of gradualness. The engine was put into mid-gear and the regulator fully

opened, and then the engine was slowly and steadily wound down so that the

train could be picked up wagon by wagon until all the couplings were taut,

and then the real get-away was commenced

McClean, H.G. (Paper 454)

The mechanical design of the latest class F high-speed electric locomotives

of the Swedish State Railways.

J. Instn Loco. Engrs, 1945,

35, 336-65. Disc. 365-77. (Paper No. 465)

E.S. Cox (369-72) spoke about Bissel trucks and Cartazzi axleboxes.

T. Robson. Counter pressure method of testing locomotives.

J. Instn Loco. Engrs, 1943,

33, Paper 441 pp. 199-200

Mainly on the electric generating test coaches which had been delivered,

but not yet used

Spencer, B. The development of L.N.E.R. locomotive design, 1923-1941.

J. Instn Loco. Engrs, 1947,

37, 212-14. (Paper No. 465)

Remarked that if it was possible to do so without disrespect to the

memory of a great locomotive engineer he would like to say that he had always

thought that Sir Nigel Gresley's policy of applying the three-cylinder design

to almost every type of locomotive was a little inconsistent. Where the power

required was greater than could conveniently be provided by two cylinders,

the three-cylinder arrangement was, of course, logical and suitable; but

for medium and low powers it was very difficult to see what advantage could

be expected from it. Mr. Bulleid had referred to the question of the turning

moment, which had always been put forward as the principal advantage of the

three-cylinder system, but which in practice and by common observation did

not give any great advantage. So far as acceleration was concerned, he himself

had never seen any test results to show that three cylinders could offer

anything more than two, and so long as a percentage of reciprocating weights

were balanced the three-cylinder engine was certainly not without a hammer-blow

effect. On the L.M.S. they had a very modern design of medium-size three-cylinder

2-6-4 tank engine, and also a larger number of two-cylinder engines of exactly

corresponding design. When those three-cylinder engines first came out their

work was carefully examined, but under no heading was any advantage whatever

found from the three-cylinder system of propulsion in an engine of that size,

and all further construction had been with two cylinders. He also commented

at length on balancing three cyclinder locomotives..

W. Vandy. Production of steel wagons.. J.

Instn Loco. Engrs, 1953, 43, 535-6. (Paper No. 526)

Suggested use of Corten, a copper bearing steel with chromium content

which was corrosion resistant and consideration of expendable wagon as

promulgated in mainland Euurope

British Railways standard steam locomotives.

London: Ian Allan, 1966. 218pp. + 41 plates (incl. 1 folding). 70 illus.,

31 diagrs. (incl. 25 s. els.), 42 tables. Bibliog. (footnote references).

Chronicleas of steam. London: Ian Allan,

1967.

Mainly autobiographical: also highly damning of certain locomotive

types, notably those from the Caledonian Railway, especially the 956 class.

Notable for drawings of proposed designed such as 2P 4-4-0 with outside cylinders

and 2-4-2T schemed during WW2.

Locomotive panorama. London: Ian Allan,

1965/6. 2v.

Vital sources of internal information both relating to the Stanier

period on the LMS and under Riddles on British Railways. Volume 1 covers

the period of Hughes and Fowler and is similar to his

Instn Loco. Engrs paper A modern locomotive

history.The second volume covers the BR Standard types again (and is

rather damning of the Clan's performance), his overseas travles, notably

to India as part ot Committee which examined derailments of the XB class.

Also covers transition to diesel and electric traction.

Terry Jenkins' biography of Sir Ernest

Lemon> makes extensive use of this work but is critical of certain aspects,

notably his comments on Hornbuckle and Fairburn..

Speaking of steam. London: Ian Allan, 1971. 128pp.

Extracts, with extensive commentary, from papers by Webb, Hughes,

Churchward, Bowen-Cooke, Fowler, Gresley, Stanier and Bulleid. Inevitably

includes extracts, and other material relating to other engineers not

included.

World steam in the twentieth century.

London: Ian Allan, 1969. 191pp. + plates.

A feature of the British school of design was the overwhelming position

of the Chief Mechanical Engineer. It has been explained how in America he

hardly existed, and, as will be seen in succeeding chapters, in many foreign

countries he had to share his design function with operators, manufacturers

and even with professors of engineering. [page 60]. Like the kings of old,

power corrupted some of them, and, surrounded by arid courtiers, they pursued

an unfruitful and autocratic way. The besetting sin of this hierarchical

structure was its isolationist nature. New designs were nursed in secrecy,

and information and drawings were only grudgingly if at all dispersed to

other CMEs.

Experiences with British Railways standard locomotives.

212-54. Disc.: 254-305. + folding plate. 4 illus., 31 diagrs., 7 tables.

Presented in London on 17 March 1954; Manchester on 24 March 1954;

Doncaster on 8 April 1954; Derby on 14 April 1954; Newcastle-on-Tyne on 22

April 1954; and Glasgow on 28 April 1954

Analysis of the performance of the locomotives in service and on test. On

page 246 rectification of lack of pre-compression on rubber drawbar springs:

graphs show the effect of modifications to No. 70004 whilst working Golden

Arrow before modification on 3 June 1952 and following modification on 14

July 1952.

At the end of the paper Cox summarised what he believed had been achieved

and the general state of the art of steam locomotive development. The steam

locomotive appears once again to have attained an almost uniform level of

potential efficiency. This point had been reached in the later designs of

the former Companies, and the B.R. locomotives working over the same temperature

range and following the same basic design, equal but do not materially exceed

the possible achievements of their immediate predecessors. It would indeed

be surprising were it otherwise, for seven out of the twelve standard types

are in essence the designs of former Companies altered only in detail, and

the other five follow the same school of design in different dimensions.

This is not to belittle the cumulative effect of small gains due to refinements

in detail, but the data set out in this paper emphasises the close identity

in efficiency between simple expansion locomotives working in the initial

temperature range 670°-750°F. in spite of the widest possible

difterences in general arrangements. Whether twin or multi-cylinders, large

or small wheels, wide or narrow grates, through considerable variations in

back pressure, and either British, German or American design, a minimum steam

consumption of 13 to 14 lb. per ihp-hour encompasses the lot, and boiler

efficiencies at normal rates of working are closely alike. Especially interesting

are the German results where an entirely independent post-war design has,

as was the case with Britannia, endeavoured to express the best which was

attainable in the conventional form. In spite of considerable differences

in some features often thought to be very important, the end result in minimum

steam consumption is very similar.

It was not always thus and a good deal of thinking on the subject is based

on conditions which no longer obtain. In 1923 and for some years afterwards,

the difference in the performance and efficiency of the products of different

designers was very real. Where steam could only get into the cylinders with

varying amounts of difficulty, and exhaust was hampered by different degrees

of obstruction, where freedom of gas flow and the whole draughting mechanism

was less well understood, then the most interesting differences occurred

in locomotive results.

Re-reading of Gresley's classic paper [not stated which] reminds us of how

valuable three paths for the steam flow instead of two were to such locomotives

as the old NER Atlantics, subject as they were to serious internal obstruction.

Other engineers found it necessary to provide fine graduations in coupled

wheel size in relation to speed which led to the idea that certain locomotives

were more suitable for particular geographical areas as indeed they were

then. With more knowledge and better materials these and other similar

conceptions have sunk back into irrelevance.

Churchward of course led the big step forward which has brought the locomotive

to its present state of relative equality. But the pupils have sat at the

feet of the master, whose familiars have in turn sat at the feet of the pupils

in the matter of superheating and a few other small matters and now all have

attained an equal state of grace, in all essentials, even if not as regards

brass-beaded splashers. Any "back to Churchward" movement would seem therefore

to be dictated more by the heart than by the head.

Compounding still offers a further reduction in steam consumption of up to

16 per cent, as the SNCF results indicate, but at a cost in complexity and

loss in availability which not only would be unacceptable in this country,

but which was partially abandoned in France in the last phase of steam in

post-war reconstruction. Further rearrangements of simple expansion without

condensing have led nowhere. The "Merchant Navy" engine has produced performance

equal to the best in the British tradition, but with a loss in efficiency

which is clearly seen in the figures quoted in this paper. The drastic changes

of the Leader could not be made to achieve even revenue earning operation.

The construction for British Railways of a single series of steam locomotives

can thus now be supported in a manner which it could not have been formerly,

on the grounds that little is to be gained from mere diversity. Controversy

naturally surrounds this question, however, the more responsible part of

which is concerned lest in exchanging four lines of development for one,

something valuable might be lost.

In January 1948, the former Companies had very little in the way of new steam

design on the stocks. Apart from the "Leader" at Brighton which was already

well in hand a class 4 2-cylinder 2-6-0 at Doncaster and small light weight

0-6-0 tank and tender engines at Swindon represents all. It can be claimed,

but not easily supported, that more advance would have been made for steam

had each regional office worked upon further versions of the previous standard

than has resulted from their working together on the B.R. series. This latter

has at least retained efficiency and performance at its present best level

and has reclothed the locomotives in a mechanical form capable of highest

route availability, of quantity production and of eventual reduction in stores

stock. To do this has required the making of a number of jigs and patterns

and the overcoming of some teething troubles, non-recurrent events which

together cost only an infinitesimal percentage of steam locomotive building

costs over, say a three-year run.

In the future, therefore, it would seem equally valid to harness the resources

of the design staffs to the further advances which seem still open- to steam

traction, amongst which may be quoted:

1. The gathering up of different sources of waste heat in the boiler -the

"Crosti" boiler now under design is an example of this.

2. Higher superheat at low rates of working.

3. Abandonment of the piston valve to solve at once both lubrication and

steam leakage problems.

4. Better understanding of adhesion, and its control under operating conditions.

5. A further onslaught on the unreliability of small details.

6. Continued attack on wearing parts for improved mileage between repairs.

CONCLUSION

We are undoubtedly entering upon the last phase of steam traction in this

country. Its disadvantages have been sufficiently publicised, and this paper

does not underplay this aspect. On the other hand, while it lasts it has

certain good features which it serves no useful purpose to 'ignore. These

are that it can be overloaded to stalling point without doing itself injury,

that its defects are easy to diagnose and seldom expensive to rectify, that

it is cheap in first cost, and, in a coal bearing country, is nearly as cheap

in fuel costs for many duties as its much more efficient and high priced

rivals. The liquidation of 19,000 steam locomotives is bound to take a number

of years, and in the meantime a certain amount of new construction will be

justified by the traffic needs. Against this background the BR series of

locomotives have made a modest contribution to our knowledge and have in

a general way achieved what they set out to do, as

listed in the original paper*. The Author sees no future whatever for

marked increase in the temperature range which alone could raise the general

efficiency level, but which requires increased space and weight which is

not available, neither does there seem any promise in novel arrangements

of the conventional ingredients. There remain, however, a number of useful

refinements capable, if proved, of application both to existing and to any

further new locomotives, which can raise the level of achievement within

the “ Stephensonian ” concept, to its optimum value, and there

is hard cash in pursuing this matter, even when the number of steam units

becomes reduced to a fraction of its present value.

Tester, Adrian, Centre

bearings, weak frames and all that. Backtrack, 2013, 27, 125.

and Tester page

Nothing E.S. Cox wrote can be taken on trust unless it can be verified

elsewhere and ideally from original sources. Examples of where he has been

economical with the truth or deliberately misleading include the following:

(i) When large lap valves were an advantage and when their presence served

no useful purpose.

(ii) Axlebox performance – that of inside cylinder engines misrepresented.

(iii) Frame performance of other older classes but no mention of the worse

track record of more modern classes, some of which he was responsible for

designing.

(iv) Misquoting dynamometer test result figures – the erroneous numbers

always support his case.

(v) Locomotive test results falsified at Rugby. To conclude, the machinations

of this very fluid writer in promoting his own biased views on locomotive

engineering have, for half a century, misled a great number of enthusiasts.

It is time his opinions are treated with scepticism – if nothing else,

one is likely to be nearer the truth!

Beavor of Steam was my calling dared to question

some of British Railkways sacred cows in the discussion on

Paper 532 :

He wrote that considerable reductions in the cost of BR Standard Locomotives

could be made. The following items are but a few of those which appear to

be very expensive, bearing in mind the present severe restrictions on capital

expenditure:

(a) Trailing truck on the Pacifics

(b) Belpaire fireboxes.

(c) Reversing mechanism.

These locomotives have numerous small pipes for remote lubrication by oil

and grease. It is very desirable that grease should be applied from a point

whence the oozing of the grease from the bearing can be observed. If this

cannot be observed then excess grease may be applied and cracked pipes may

not be noticed. The provision of so many lengthy pipes must surely add to

the cost of these engines. The writer would point out that there are a number

of inconsistencies due to various parts of the same engine being designed

in different drawing offices. A good example of this may be found in the

fastening of the valve crosshead guides, where the bolts are fitted with

split flat cotters. Yet on those engines having underslung crossheads of

LNER type the slide bar bolts are only fitted with split, pins! Clearly the

slide bar bolts carry much greater vibrating forces than do the bolts of

the valve crosshead guides. It wouId seem that early opportunity should be

taken to fit the slide bar bolts also with split flat cotters. There is,

no doubt, further scope for detailed investigation to remove similar anomalies

in the design of existing and future BR Standard Locomotives.

Cox's reply: Mr. E.S. Beavor criticises three features as being unduly costly.

The trailing truck, based on the SR design is not specially expensive as

trailing trucks go. The Cartazzi arrangement is cheaper, but is technically

less satisfactory and is seldom used over the world in general. The Belpaire

firebox may be marginally dearer to build but is more economical in maintenance

cost, and gives much better steam release conditions at high rates of working.

It is significant that three out of the four former Companies used it. The

reversing mechanism was made more expensive deliberately to try to get improved

service out of what is often a rackety piece of mechanism. It has shown certain

defects it is true, but these are not necessarily best overcome by making

the job cheaper. The grease lubrication system is working very well, which

it certainly would not do if the nipples were tucked away out of sight so

that their greasing was overlooked. It would be miraculous if there were

no inconsistencies, especially as a good number of actual regional parts

have been incorporated. The Author notes the example of the slide bar bolt

split pins

| RETURN TO Home Page Top of this Page |

|

| Registered Charity No 290944 | Company Limited by Guarantee No 1862659 |